Kohler WaterDeck

PRECISE POWERFUL CONTROL OF MOISTUREWaterDeck allows the operator to change the warp profile of the board in seconds while maintaining constant corrugator settings.

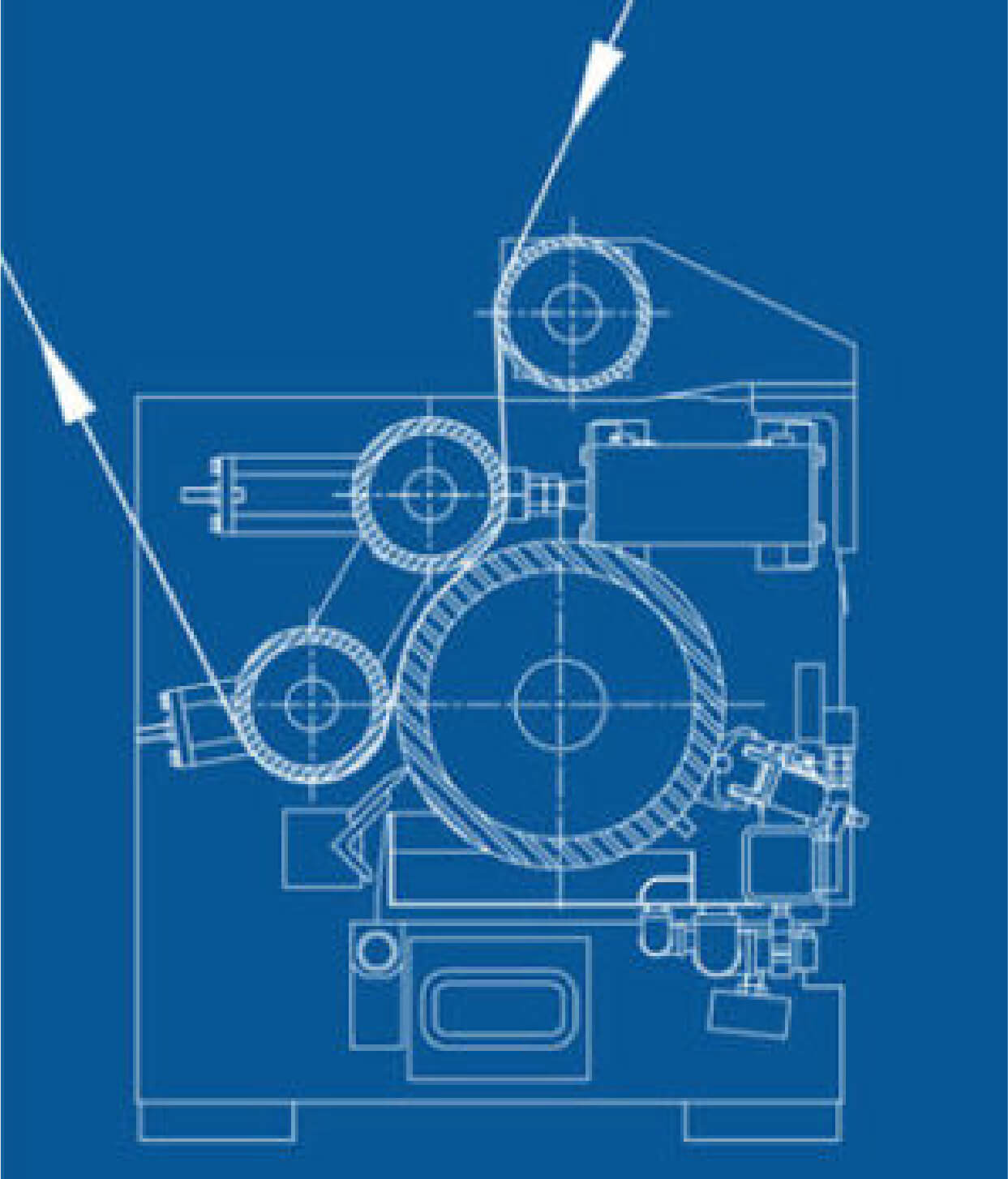

Kohler WaterDeck on the SF liner

Water film thicknesses as low as 0.5 micron (0.00002”) uniformly applied over an application range of 900 to 1 controlled by an A.C. vector motor.

- Works with any level of corrugator automation and vastly simplifies operator intervention.

- Eliminates bonding, edge delam and score cracking issues.

- Reduces wash boarding.

- Increases speed, especially on difficult grades.

- Lowers the total amount of water used in the process.

- Faster order changes with reduced waste by eliminating most preheater, glue gap and other control changes.

Our proven Hydros training program strengthens the corrugating knowledge of your entire team and combines with Kohler WaterDeck technology to provide powerful correction of warp, score cracking, and bonding problems.

Together we’ll pick a location based on your needs:

- SF Liner

- DF Liner

- SF Medium

- SF Web at the Triple Stack

Then use the three HYDROS strategies to achieve your goals:

- Replace starch with water

- Manage paper moisture

- Protect your paper properties